Case Study

Project Name – International Management Institute, Kolkata

Total Built Up Area – 1.5 Lakhs Sqft (Main Academic block)

Scope of Work – Sustainable Energy Audit

Completed within 15 days from the date of receipt of LOI

Energy audit for International Management Institute, Kolkata carried out through the preliminary analysis and detailed energy calculations-financial analysis of proposed Performance Improvement Measures (PIM). The financial analysis provides the facility team the understanding of the financial benefits in implementing specific Performance Improvement Measures. Utility bills were collected for 12 months period to allow the auditor to evaluate the facility’s energy/demand rate structures and energy usage profiles. A detailed financial analysis is performed for each measure based on implementation cost estimates; site-specific operating cost savings, and the customer’s investment criteria. Sufficient detail is provided to justify project implementation.

Since the facility is an educational institution, the operational hours of the classroom varies day to day, to assess the energy saving potential operational hours is important criterion, this made a critical study to find out the operational hours. And the facility doesn’t have the design details for the HVAC, audit team evaluates through the ASHRAE baseline with present operational category to find out the gaps and improvement measures.

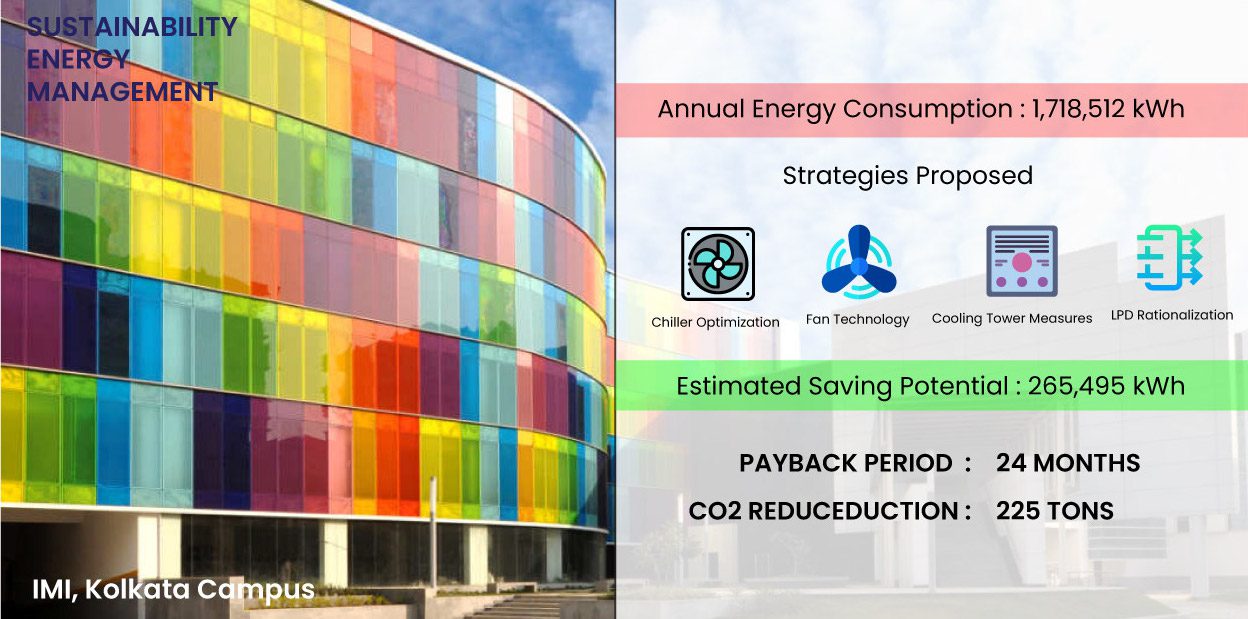

The overall annual energy consumption for the building is 1,718,512 kWh/annum & energy bill of Rs 178 lakhs/annum. The annual greenhouse gas emissions equivalent for electricity is 10,460 tons of CO2 (0.85kg of CO2 emits /kWh of unit generation).

The assessment of identified Performance Improvement Measures (PIMs) are categorized under

| Overall Performance Improvement Measures (PIMs) | Annual Energy savings kWh | Annual savings, Lakhs | Cost of Measure, Lakhs. | Payback Months |

| No/Low Cost – Operational Improvement | 21,817 | 2.4 | 2.1 | 6 |

| Medium Cost – Design Enhancement | 81,930 | 8.6 | 14.4 | 20 |

| High Cost – Technology Advancement | 161,748 | 17.0 | 38.0 | 27 |

| Total | 265,495 | 28.0 | 54.5 | 24 |

Overall 15% i.e. 265,495 kWh units savings identified on above mentioned categories with average payback of 24 months and reduced annual greenhouse gas emissions equivalent to 225 tons of CO2.

To enhance their energy management and saving potential, we identified key areas of improvement in chiller, AHU, Base energy consumption etc. Through our expertise in energy measurement and verification, we proposed number of energy measures, which could result in 15% of energy savings per year.