Gloster Nuvo Limited set out to develop a production facility that ensured optimal ventilation without relying on HVAC systems, while maintaining thermal comfort for its workforce, a challenging task given the context.

·A massive 120m x 280m footprint, which can cause air stagnation in central zones.

·High ambient humidity in Kolkata’s tropical climate, intensifying occupant discomfort

·Disrupted natural airflow caused by adjacent buildings interfering with prevailing wind patterns in some places

·Inadequate daylight distribution and glare in workspaces.

Through sustainable design analysis, we engineered data-driven solutions to transform the facility into an IGBC-compliant, high-performance space. Here’s how:

Climate & External CFD Key Insights:

o Predominant winds from the South/South-East (31.85% of annual hours).

o Low wind speeds (0.5–1 m/s) during summer worsened stagnation.

· Interventions (proposed):

o Windward openings (South/South-East facades) to capture prevailing winds.

o Ridge vents/turbo ventilators at roof level (neighbouring buildings were lower, enabling the stack effect).

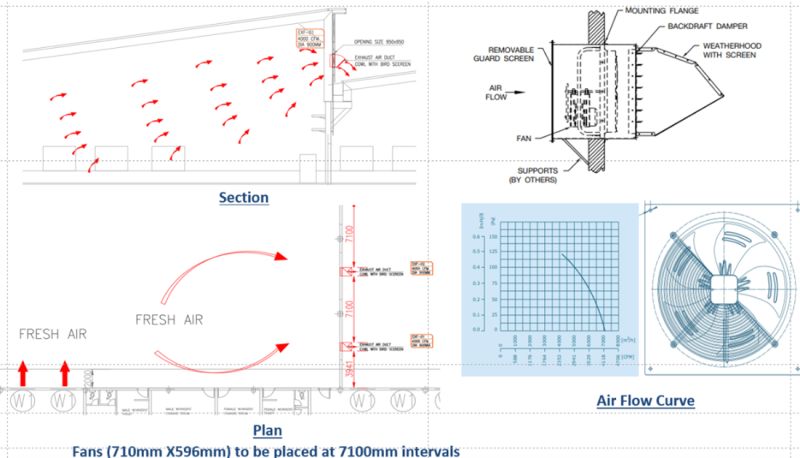

o Zonal fan placement to accelerate airflow in low-velocity zones.

Daylight & Glare Analysis: Balancing Light and Comfort

Key Interventions:

o North Light Glazing: Optimised window-to-wall ratio and truss sizing.

o Glare Control: Reduced glare from 10.4% to 0.1% post-3 PM.

Results:

89.5–95.4% of workspaces achieved ideal daylight (300–3000 lux).

Maximum IGBC points secured for daylighting (100% compliance).

Internal CFD: Tackling Stagnation & Humidity

Problem: Just 5.3 ACH (vs. NBC’s 8–10 ACH standard).

Solutions:

o 15 propeller fans (4000 CFM each) per bay

o HSLV (High volume low speed) fans for targeted airflow.

o Automated linear actuators on vents + CO₂/temperature sensors for dynamic control.

o Leeward louvers at height to induce stack effect.

Results:

ACH boosted to 8.71 (meeting NBC).

4/4 IGBC points for Fresh Air Ventilation (4.18% openable area ratio).

1.2°C average temperature drop in core areas.

Why This Matters

🔹 Worker Productivity: Stable thermal comfort (per ASHRAE 55) and glare-free light reduce fatigue.

🔹 Energy Savings: 25% lower lighting energy + dynamic fan control cut operational costs.

“Gloster Nuvo proves sustainable design drives productivity & savings, even in challenging climates. Ready to transform your industrial space into a high-performance, certified asset? DM us! Email: info@conserveconsultants.com | Call: +9190030 97071 Website: https://lnkd.in/dThYxcG2 to build smarter, greener, and fairer.

CII Godrej Green Business Centre |CII – Indian Green Building Council (IGBC) |CREDAI National

hashtag#SustainableDesign hashtag#GreenBuilding hashtag#HighPerformanceFacility hashtag#IndustrialDesign hashtag#Certification hashtag#EnergyEfficiency hashtag#VentilationSolutions hashtag#DaylightOptimization hashtag#SmartManufacturing